China’s next-generation solution for nuclear waste management and fissile material breeding – the ADS system

Special Issue #4

In this issue:

What is the ADS concept?

How can ADS systems breed fissile materials or resolve issues of long-term nuclear waste management?

How is China advancing its ADS program?

What are the nonproliferation and safeguards implications of ADS technology?

China is at the global forefront of developing a nuclear energy device that requires neither fissile nor fertile materials to operate and that has the potential to fundamentally resolve the issues of reactor safety and long-term nuclear waste management. The solution, known as the accelerator-driven subcritical (ADS) concept, was first proposed by U.S. and European scientists in the early 1990s, though China has been the first to begin the construction of a large-scale ADS facility.

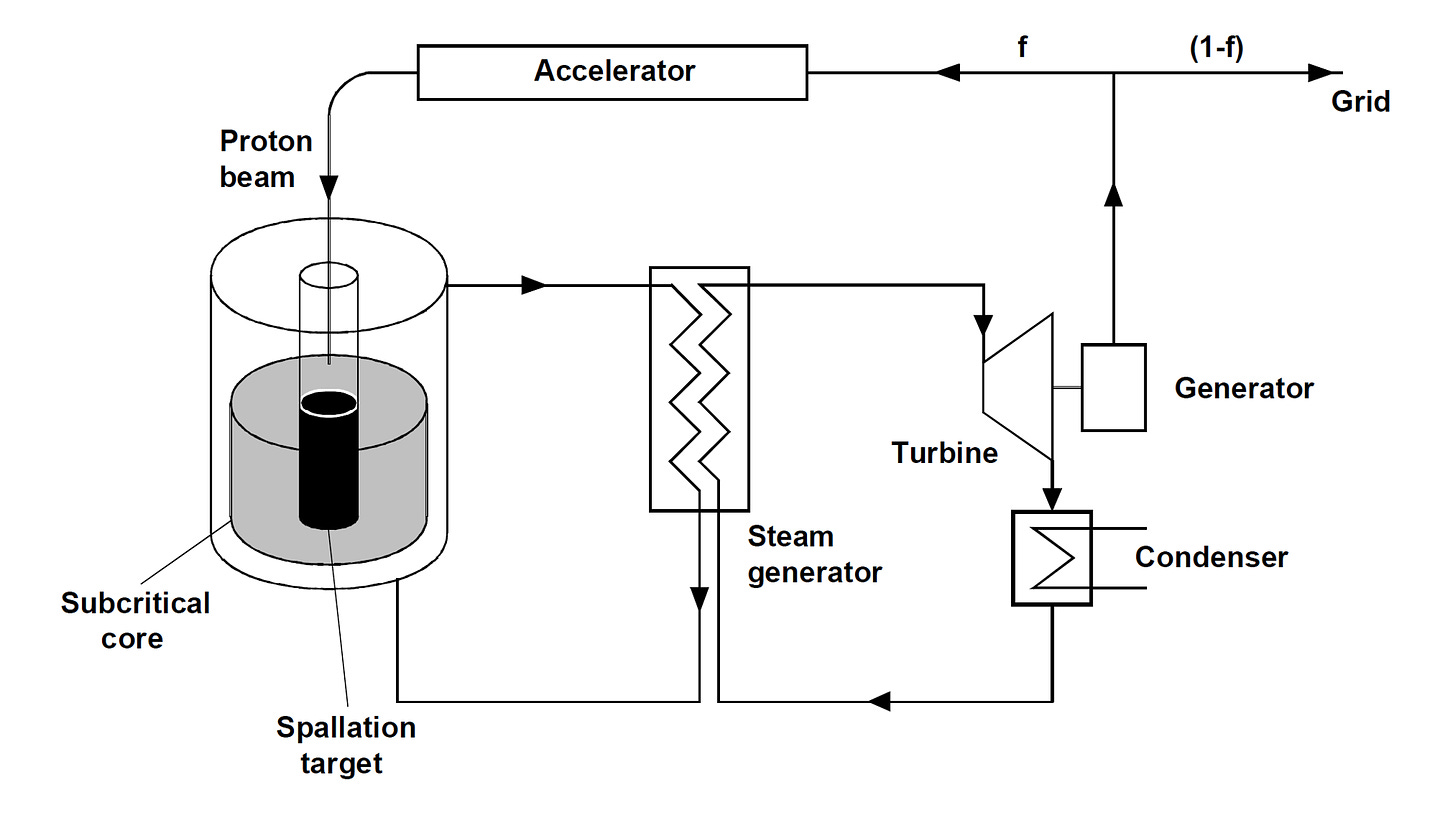

Whereas traditional nuclear reactors operate in a critical mode, meaning the fission reactions within the core are self-sustaining, an ADS reactor is able to operate in a subcritical mode where fission reactions are sustained with an external neutron source. That source is a proton beam accelerated to hundreds of MeV, impacting a heavy metal target made of lead, tungsten, or their alloys inserted in the middle of the reactor core. Through a complicated cascade of reactions, the impact releases a large number of neutrons – a process referred to as “spallation.” These neutrons then transmute – or burn away – materials in the reactor core, which may include not only fissile and fertile nuclei but also minor actinides accounting for the vast majority of the radiotoxicity in high-level nuclear waste, or spent fuel, past hundreds of years. In addition, an ADS system may be configured to generate power or to breed fissile materials. Compared to traditional critical reactors, an ADS reactor would have superior safety characteristics since reactions in the core are sustained with an external neutron source, which can be used to regulate the power of the reactor without control rods.

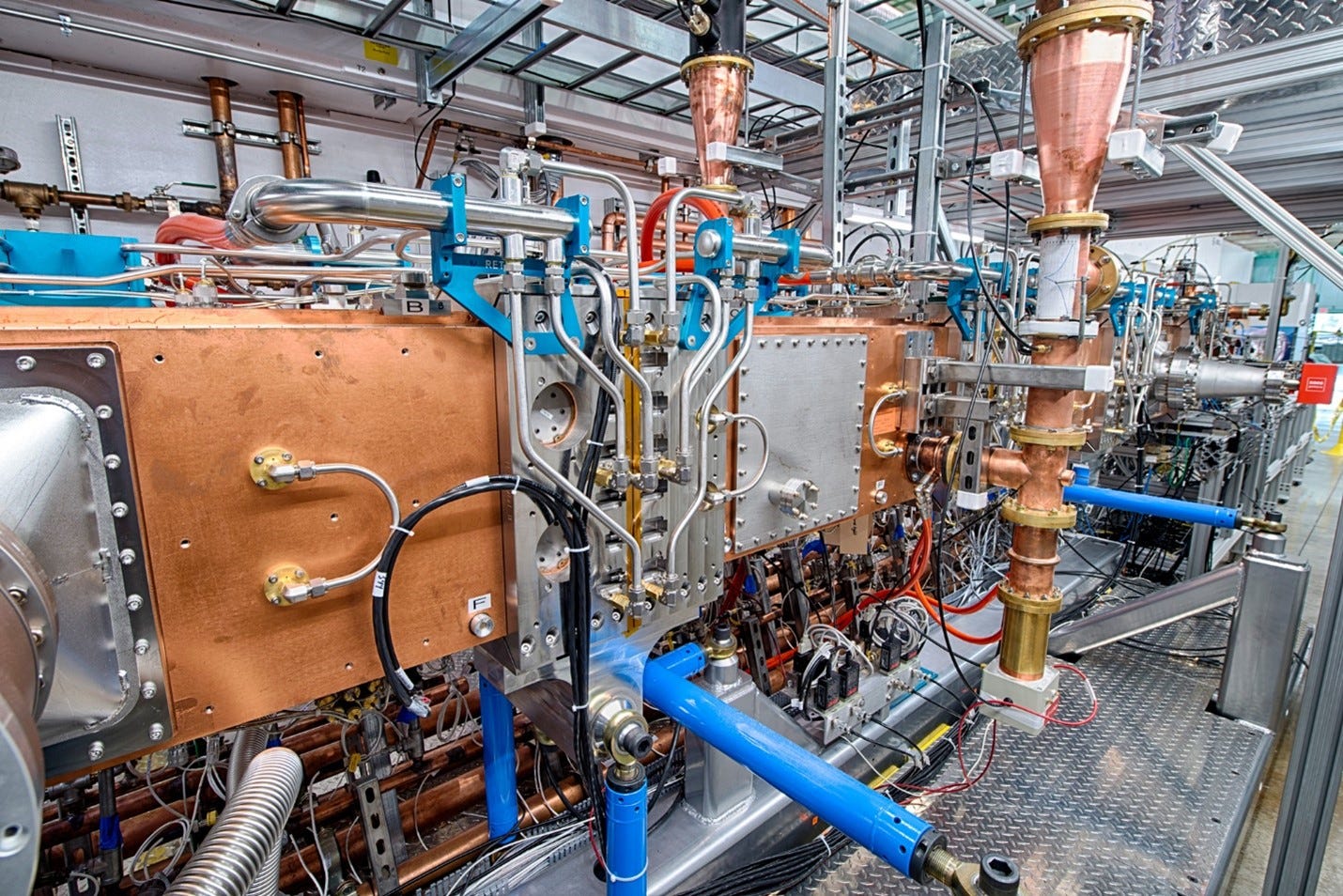

Despite the simplicity and appeal of the ADS concept, building an ADS system requires advanced technologies such as high-energy superconducting particle accelerators, without which electrical resistance would convert a significant amount of the energy intended for the particle beam to heat, degrading the efficiency of the accelerator and making continuous operation infeasible. The only way to eliminate electrical resistance is to cool the cavity of the accelerator to a temperature close to absolute zero to enable superconducting properties. Another challenge is designing a target made of spallation-conducive material in an optimal physical form to maximize stable circulation and heat transfer while minimizing corrosion, just to name a few important requirements. The use of lead-bismuth eutectic (LBE) as the coolant of the subcritical reactor also requires extensive research and development.

Principal fuel cycle schemes with the introduction of ADS systems | Source: NEA/OECD

A power-generating ADS system | Source: NEA/OECD

The radiofrequency quadrupole and superconducting radiofrequency cavity of Fermilab’s PIP-II linear accelerator | Source: Fermilab

The use of accelerators for the breeding of fissile materials was explored early in the nuclear age. The first such effort was Lawrence Livermore’s Materials Testing Accelerator (MTA) program (1949-1954), which aimed at developing a linear accelerator to produce neutrons for the breeding of Pu-239 and U-233, with the objective of making the United States independent from foreign uranium supplies. The program was terminated in the mid-1950s with the discovery of domestic uranium deposits deemed sufficient to guarantee the requirements of the U.S. nuclear program. China undertook a similar effort to explore the breeding of Pu-239 with accelerators for the purposes of weapon production. The program was terminated in 1971 due to technical limitations on accelerator performance.

In the early 1990s, interest in accelerator-driven systems was revived due to the perceived potential of the partitioning and transmutation (P&T) strategy for nuclear waste management. Beyond 300 years, the vast majority of the radiotoxicity of high-level waste will come from transuranic elements composed of plutonium and the minor actinides. Some countries are currently implementing a MOX-fuel-based high-level-waste management strategy, which entails separating the plutonium from spent fuel to be burned in light-water reactors and fast reactors. Yet a partitioning and transmutation strategy using ADS systems is much more efficient since the core of a subcritical reactor can be composed purely of plutonium and minor actinides. Whereas reactor control requirements limit the fraction of minor actinides in a critical fast reactor to between 2% and 5%, a subcritical reactor has no such limitations. As a result, ADS systems have a much higher supplier-to-burner support ratio even compared to critical fast reactors, meaning a single ADS facility can satisfy the nuclear waste burning requirements of a large number of light-water reactors.

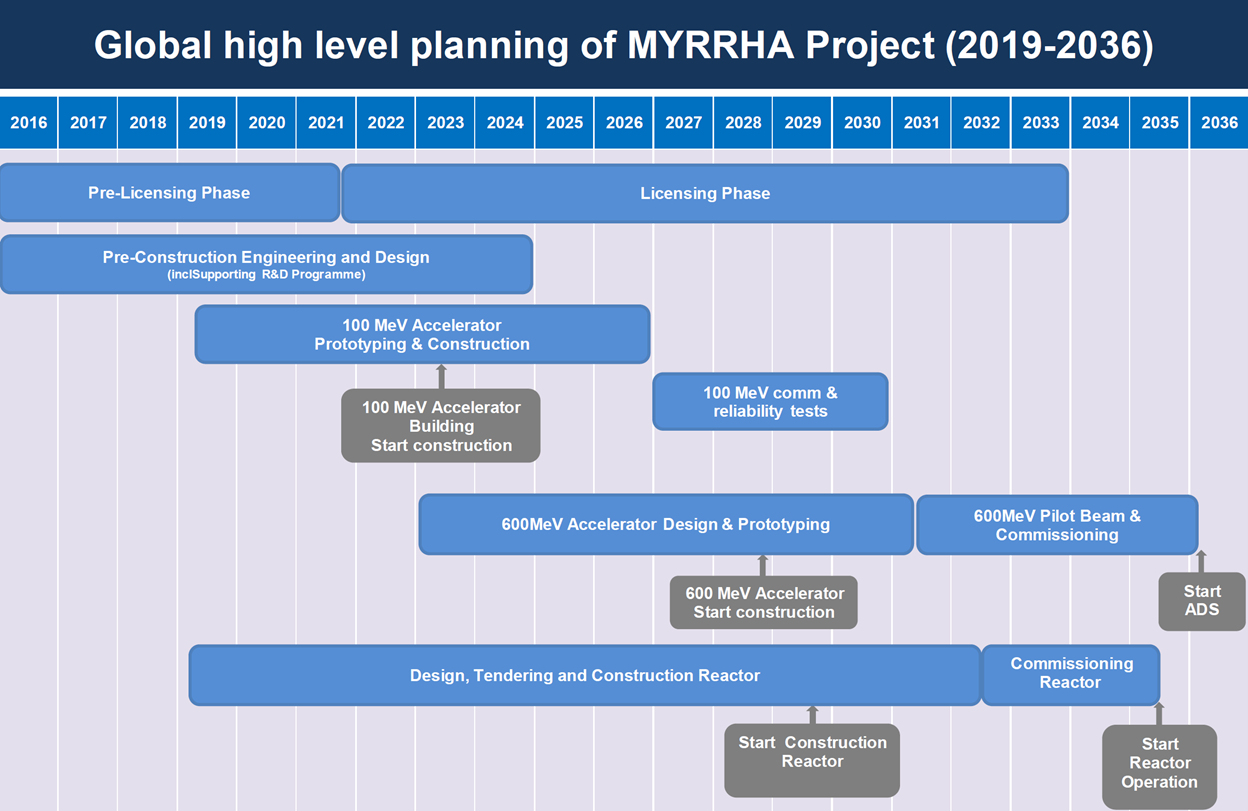

In the late 1980s and early 1990s, C. Bowman at Los Alamos National Laboratory and H. Takahashi at Brookhaven first proposed using ADS systems for thermal and fast neutron spectrum transmutation and energy production. By 1994, C. Rubbia at CERN had developed a more detailed “energy amplifier” concept, thus laying the foundation for a series of European ADS research efforts like the PDS-XADS, which yielded the multi-purpose hybrid research reactor for high-tech applications (MYRRHA) project. In late 2022, the Belgian government approved the construction of MYRRHA at the SCK-CEN complex in Mol, meanwhile committing €558 million towards the first phase. The system will feature a linear accelerator capable of boosting the energy of the proton to 100 MeV over 150 meters, to be upgraded to 600 MeV in future phases. The reactor, to be constructed subsequently, will be lead-bismuth cooled, with a maximum power output of 100 MWt.

A CGI of MYRRHA, to be constructed at the SCK-CEN complex in Belgium | Source: MYRRHA

The SCK-CEN complex | Source: Airbus

The MYRRHA Project timeline | Source: JAEA/J-PARC

The U.S. Department of Energy, as part of the Russian Research Reactor Fuel Return (RRRFR) program, agreed to fund the design and construction of an ADS demonstration facility at the Kharkiv Institute of Physics and Technology (KIPT). The LEU-fueled, electron accelerator-driven subcritical assembly started up in August, 2021, 6 months before the war. The facility was subsequently damaged by shelling and has not been repaired.

The KIPT neutron source facility in June, 2016 | Source: Argonne National Laboratory/NNSA

KIPT general director Mykola Shulga in front of the KIPT neutron source facility, more than a year after missile barrages damaged the structure | Source: AP News

While China is a latecomer to accelerator R&D, it did not lag behind the rest of the world in exploring the ADS concept. Researchers at the China Institute of Atomic Energy (CIAE) first began studying the ADS concept in the 1990s. A conceptual research team was established with the support of industry as early as 1995, completing a five-year study by 1999. Thereafter, fundamental research continued under two five-year projects funded by the “973” National Basic Research Program, starting in 2000 and 2007, respectively. In 2010-2011, the Chinese Academic of Sciences (CAS) proposed a 3-phase ADS development roadmap under the ADS special project* – part of the CAS Innovation 2020 program, which the State Council reviewed and approved during its 105th executive meeting on March 31, 2010. The first phase foresaw the construction of an ADS transmutation research device for theoretical verification; the second phase sought a demonstration device for technological validation; and the third phase envisioned industry-scale introduction of ADS technology as an integral part of China’s closed nuclear fuel cycle. The goal of the Chinese ADS program is to reduce the volume of high-level waste by 96% and shorten its radiotoxic lifetime to within 500 years.

*Advanced future nuclear fission energy was among the four inaugural projects in sub-type A, designated “forward-looking strategic science and technology” (前瞻战略科技) in the CAS system of “special projects” (科技专项) spanning 5 broad categories. The ADS project and other projects in its category are approved by the State Council and described as having the potential to enhance “the country’s international competitiveness, long-term sustainable economic and social development, and national security” while matching “potential directions of the new scientific and technological revolution.”

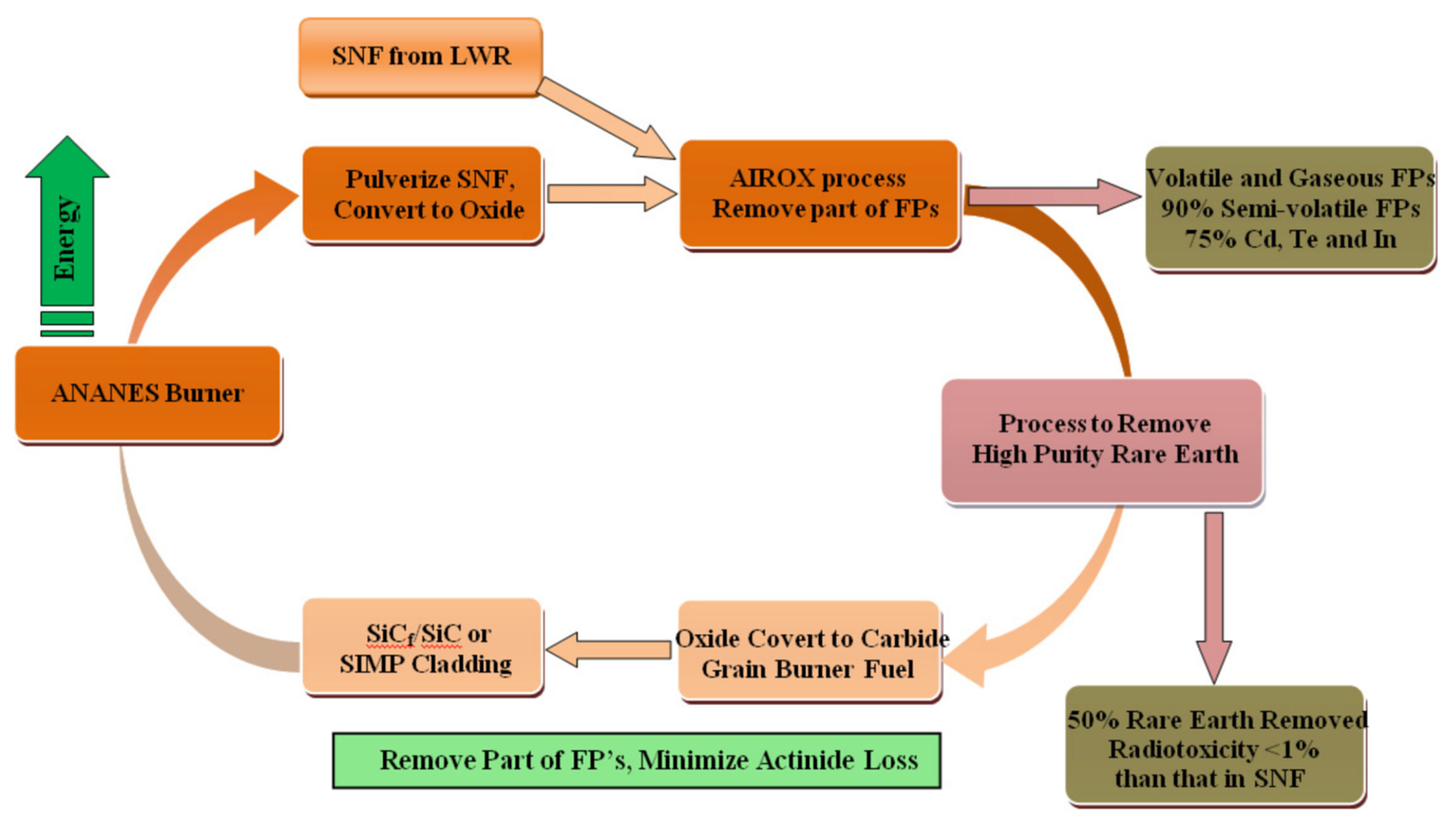

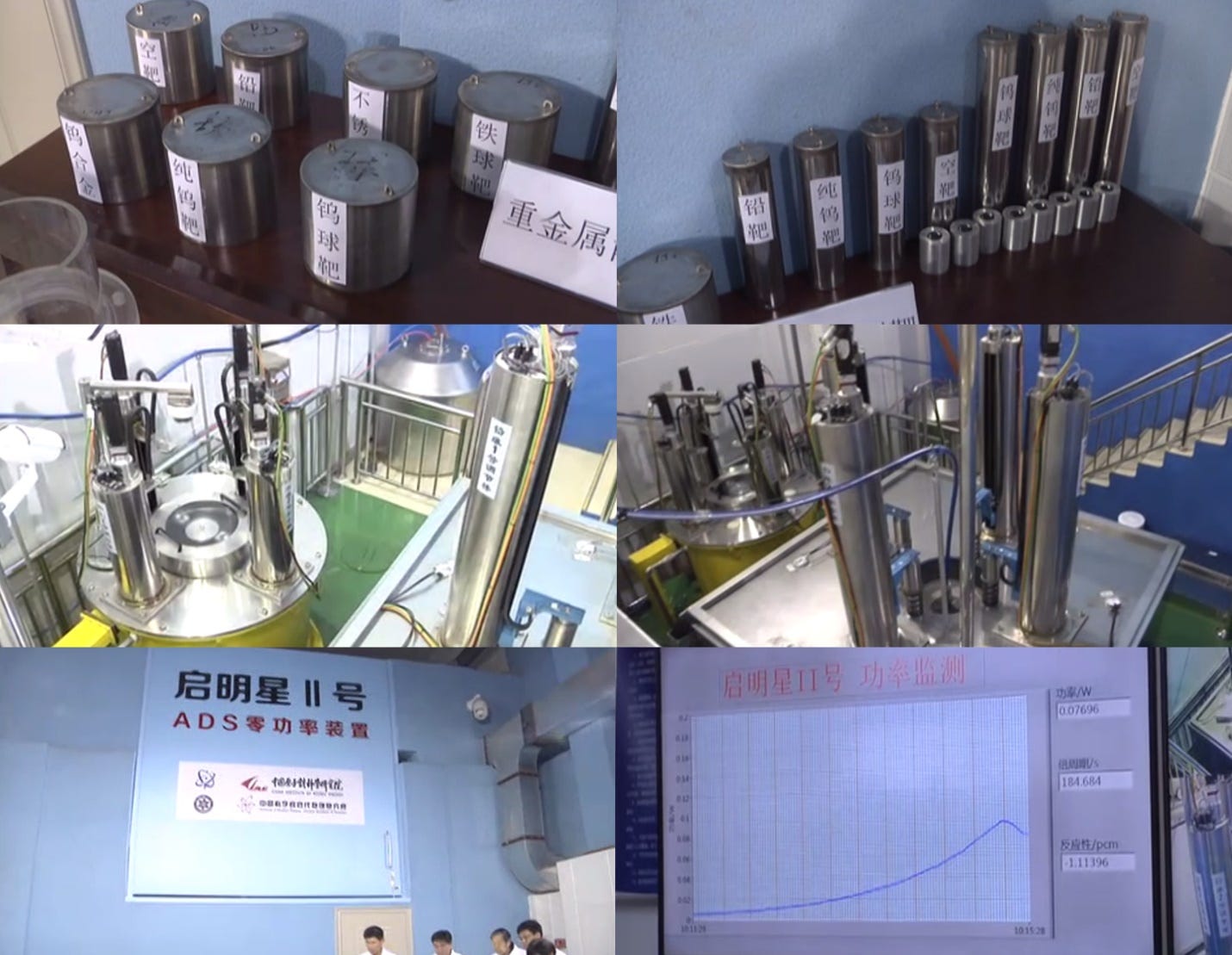

The major accomplishments of the ADS special project by the time of its conclusion in 2017 included the assembly of the linear accelerator front-end prototype, the development of the dense granular-flow target concept and associated technical verification, the construction of the world’s first ADS zero-power device, in addition to non-nuclear test devices for lead-bismuth reactors, and breakthroughs in structural materials. In the process of advancing the project, Chinese researchers further developed the accelerator-driven advanced nuclear energy system (ADANES) concept, which expanded beyond the transmutation of nuclear waste to fissile material breeding and power generation. In addition to a burner (ADB, 加速器驱动燃烧室) consisting of an accelerator, spallation target, and subcritical reactor, the ADANES will also feature an ADRUF (accelerator-driven recycle of used fuel, 加速器驱动乏燃料再生) complex for the reprocessing of LWR- and ADB-generated spent fuel. The ADB will be capable of burning reprocessed spent fuel containing around 50% fission products, with a refueling cycle of 16 to 36 years. The ADANES fuel cycle is illustrated below.

The ADANES fuel cycle | Source: Xuesong Yan, Lei Yang, Xunchao Zhang and Wenlong Zhan, “Concept of an Accelerator-Driven Advanced Nuclear Energy System,” Energies 10, no. 7 (2017): 944

According to the ADANES proposal, the subcritical reactor would start up with a small amount of U-235 fuel to transmute minor actinides and fission products while breeding Pu-239 from U-238. At the end of the first burn-up cycle, the bred Pu-239 would exceed the U-235 consumed, thus providing sufficient startup fuel for the second cycle in the full subcritical mode. Alternatively, the core may be configured so as to breed enough fissile materials during the cycle to switch from subcritical to critical operation after 5 years. In this mode, two accelerators can be coupled with 8-10 reactors to minimize construction costs.

The ADANES concept has secured the support of state ministries and regulatory agencies, which, after a joint review, approved a four-phase roadmap, with phase I being the ADS special project. Phase II will involve the construction of an initial ADS facility and validation of the ADRUF, and Phase III – the construction of a 100 MW-rated ADANES industrial demonstration facility, followed by enterprise-led commercial deployment in phase IV. In March, 2016, the Chinese Academy of Sciences signed a strategic cooperation agreement with China General Nuclear Power Corporation (CGN) on the research and development of the ADANES system. The development and construction of the initial facility, or the China initiative Accelerator Driven System (CiADS), by CAS in collaboration with CIAE and CGN has been ongoing.

China’s ADS/ADANES roadmap | Source: Institute of Modern Physics

The CiADS construction site at the Renping Peninsula Energy Center, Huidong County, Guangdong Province | Source: Institute of Modern Physics

CiADS is a critical component of the ADS and ADANES roadmap. China claims it will be the world’s first MW-rated ADS device and will lay the foundation for the industry-scale demonstration of ADS systems. In January, 2013, the State Council approved by executive meeting the construction of the CiADS as a priority technology infrastructure project. The construction site was selected in 2014. The feasibility study was approved by the State Development and Reform Commission in January, 2018. Construction began in July, 2021, and is expected to require 6 years.

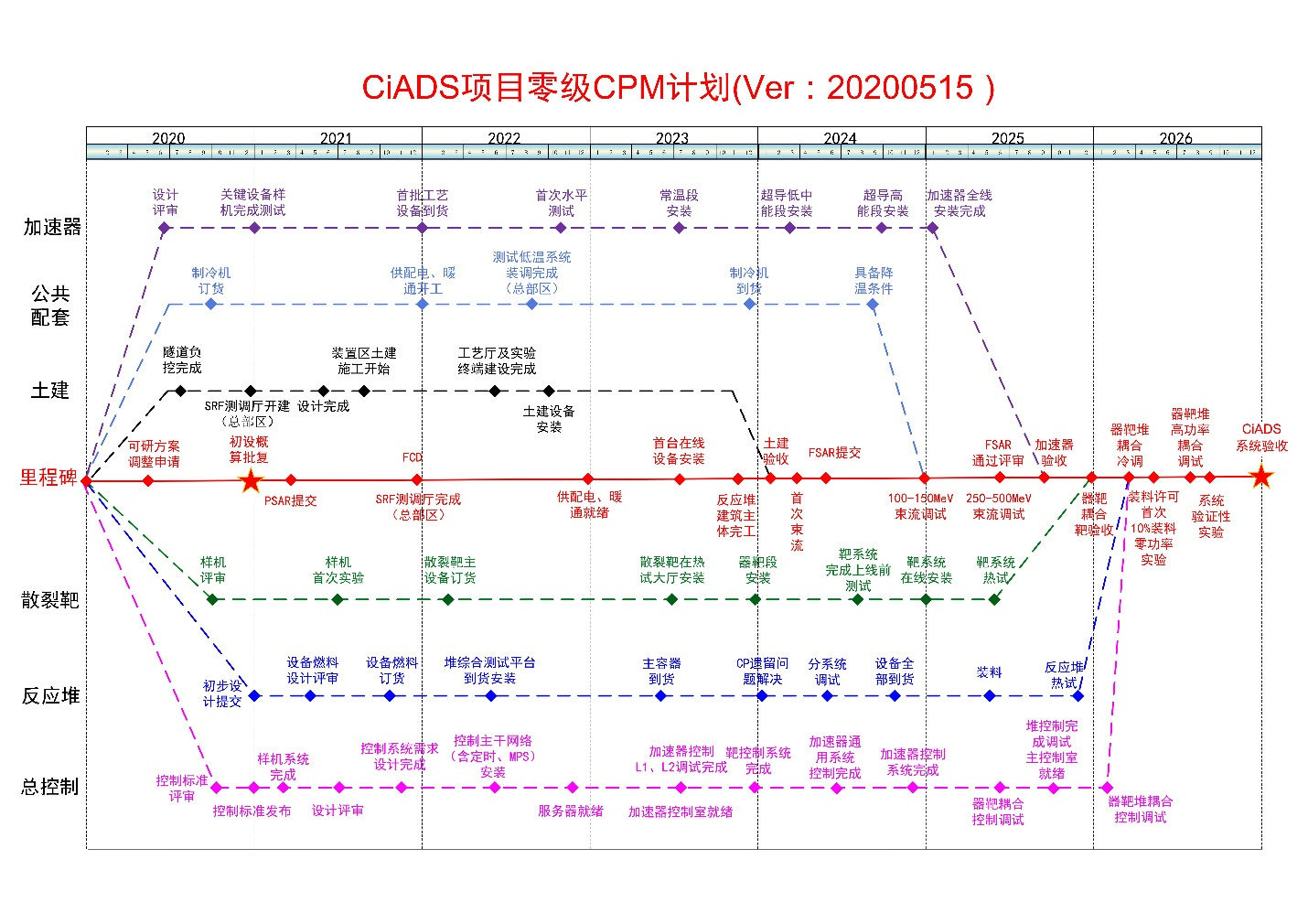

The CiADS project timeline (2020 version). From top to bottom, the sub-timelines are labeled accelerator (violet), public infrastructure (light blue), civil construction (black), spallation target (green), reactor (dark blue), and overall supervision (purple). The device as a whole will be completed in 2026 | Source: Institute of Modern Physics, CAS

A CGI of the CiADS and adjacent HIAF | Source: Institute of Modern Physics, CAS

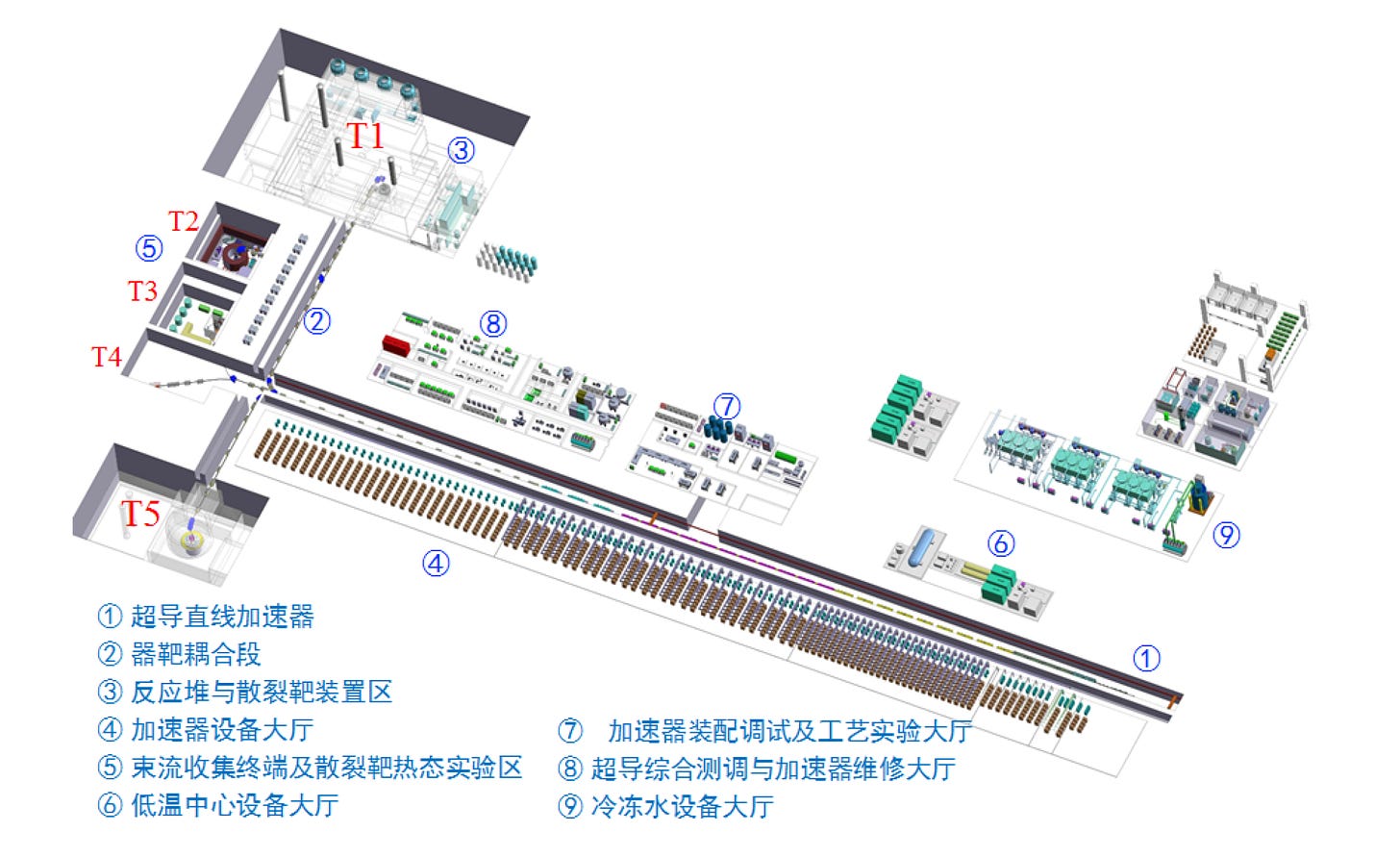

The CiADS facility | Source: Institute of Modern Physics, CAS

The CiADS device involves a linear accelerator, a lead-bismuth spallation target, and a subcritical reactor. The linear accelerator is 350 meters long and capable of accelerating a beam of protons to an energy of 250 MeV, with the potential for upgrades. The CiADS environmental impact report approved by the Ministry of Ecology and Environment stipulates an upper bound of 500 MeV, though the Institute of Modern Physics claims upgrade is possible up to 1.5 GeV. The beam will require 2.5 MW of power, out of the device’s 10 MWt power output.

CAS announced in 2014 following an interim evaluation of the ADS special project that it had succeeded in developing the world’s most powerful radiofrequency quadrupole (RFQ) accelerator and made key technological breakthroughs in low-beta superconducting spoke cavities and half-wave resonator (HWR) cavities. The ion source and RFQ belong to the room-temperature front end of the linear accelerator, and the superconducting cavities are connected to the front end via a medium-energy beam transport line. Cooled by cryogenic technology, the superconducting cavities are responsible for accelerating the proton beam to the hundreds of MeV required for spallation reactions to take place. Protons exiting the superconducting cavities are transported via a high-energy beam transport line to the lead-bismuth eutectic (LBE) hot window target. The hot window refers to the entrance of the proton beam into the target material. The alternative is a windowless target unit, which eliminates issues arising from the exposure of structural material to proton irradiation but introduces complications associated with direct contact between the proton beam and LBE.

China’s linear accelerator front end prototype | Source: Huihong Li, Weiqun Shi, Wenlong Zhan, Zhifang Chai, and Guoxuan Dong, “Review of Major Research Plan on ‘Future Breeding and Transmutation’ in Advanced Nuclear Fission Energy,” China Science Foundation 35 (3): 451-457

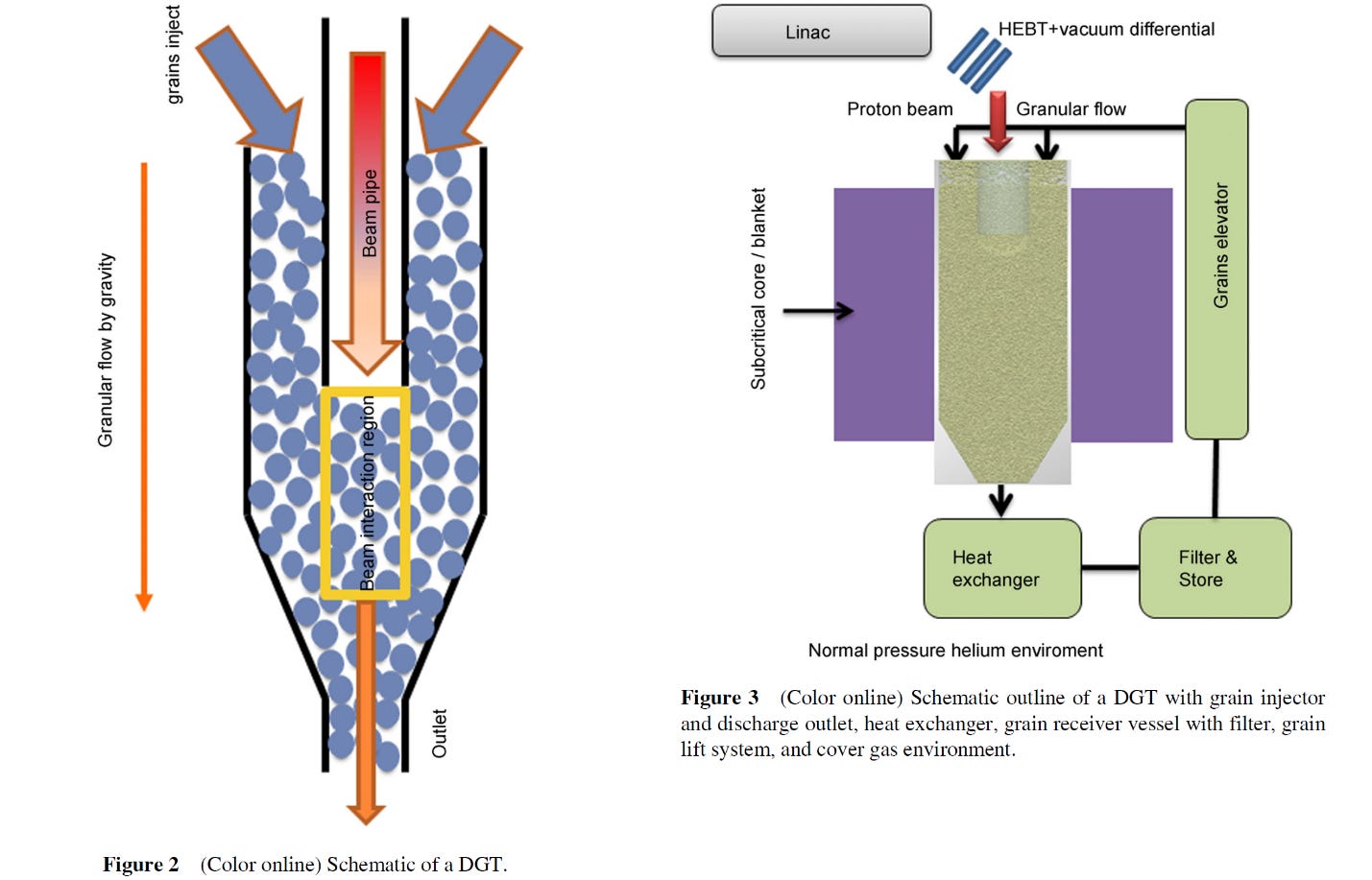

The CiADS will utilize a lead-bismuth target, which has already been tested via the Institute of Modern Physics and Dongjiang Laboratory’s jointly developed prototype. However, future devices will likely transition to the gravity-driven dense granular-flow target (DGT), expected to eliminate drawbacks of LBE targets such as thermodynamic instability, corrosion, and toxicity. Characterized as a “large collection of discrete solid particles” displaying “both solid and fluid behaviors,” DGT offers such advantages as “high neutron yield, low radiotoxicity, high specific capacity and thermal conductivity … low chemical toxicity and low corrosion” compared to heavy liquid metal targets. Testing has demonstrated promising performance in 1-millimeter tungsten-nickel alloy particles.

The gravity dense granular-flow target (DGT) concept | Source: Lei Yang and Wenlong Zhan, “New Concept for ADS Spallation Target: Gravity-Driven Dense Granular Flow Target.” Science China Technology Sciences 58 (2015): 1705-1711

CiADS spallation target prototype | Source: Institute of Modern Physics, CAS

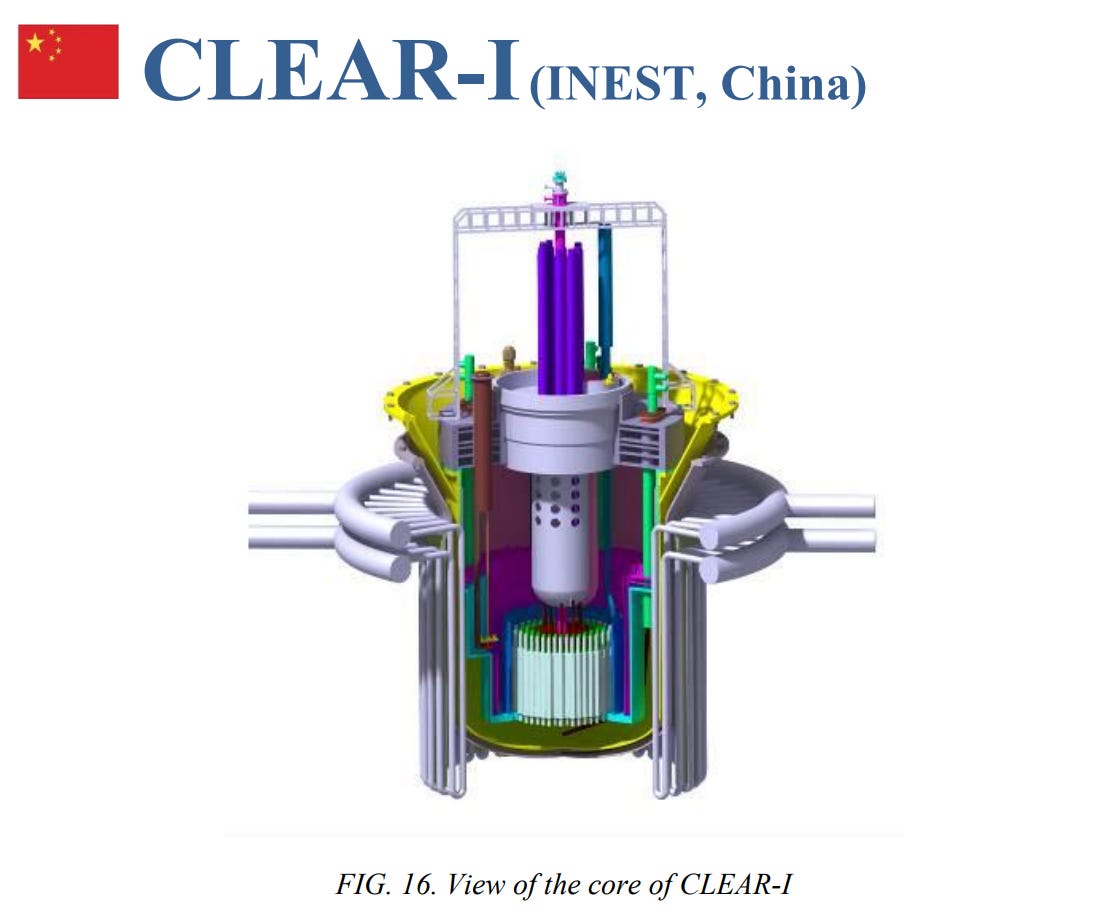

For the subcritical reactor of its ADS burner, China has adopted as reference the CLEAR lead-bismuth-cooled reactor concept developed by the FDS team at the Institute Nuclear Energy Safety Technology (INEST), Chinese Academy of Sciences. Lead is favored for nuclear waste transmutation and fissile material breeding because of the low likelihood of neutron absorption and moderation in lead material. In addition, its low melting point and high boiling point allow for coolant circulation at atmospheric pressure with significantly lower risks of a loss-of-coolant accident.

First in the CLEAR series is the 10 MWt research and experimental reactor, CLEAR-I, with the ability to operate in both critical and subcritical modes so as to enable neutronic, thermohydraulic, and safety experiments contributing to both critical fast reactor and ADS development | Source: IAEA

As part of the reactor development effort, INEST has constructed the CLEAR-S non-nuclear device for the verification of engineering solutions for lead-cooled reactors in an integrated system (铅基核反应堆工程技术集成验证装置). Equipped with electrically heated nuclear fuel simulators, the device is operated to verify in-core heat transfer and coolant flow distribution characteristics while testing full-scale prototype components in support of CLEAR-I’s license application. Meanwhile, the neutronics data will come from the CLEAR-0 zero-power reactor with a solid lead-bismuth coolant simulant.

Another experimental device is the KYLIN-II large lead-bismuth test loop (大型铅铋实验回路), which may be used for thermodynamic, thermohydraulic, and safety testing as well as the verification of corrosion-resistant structural materials. In addition, such test loops are key for verifying oxygen monitoring and control technologies. On the one hand, the formation of lead and bismuth oxides can disrupt coolant flow and degrade its heat transfer properties. On the other hand, an oxide layer may help protect structural material from LBE corrosion. The oxygen concentration in the LBE coolant must therefore be precisely monitored and controlled.

The KYLIN-II test loop | Source: INEST

(a) CLEAR-S, (b) CLEAR-0, and (c) CLEAR-V, a virtual reactor for design analysis and operator training | Source: INEST

The China Institute of Atomic Energy (CIAE), as another stakeholder in the reactor component of the ADS project, has built additional test facilities such as the lead-bismuth heat convection experimental device that began operating in early 2018. Constructed over some 150 days, the device served to simulate the corrosion of ADS structural materials for early material selection and demonstrate oxygen control in high-temperature liquid LBE at low flow rates.

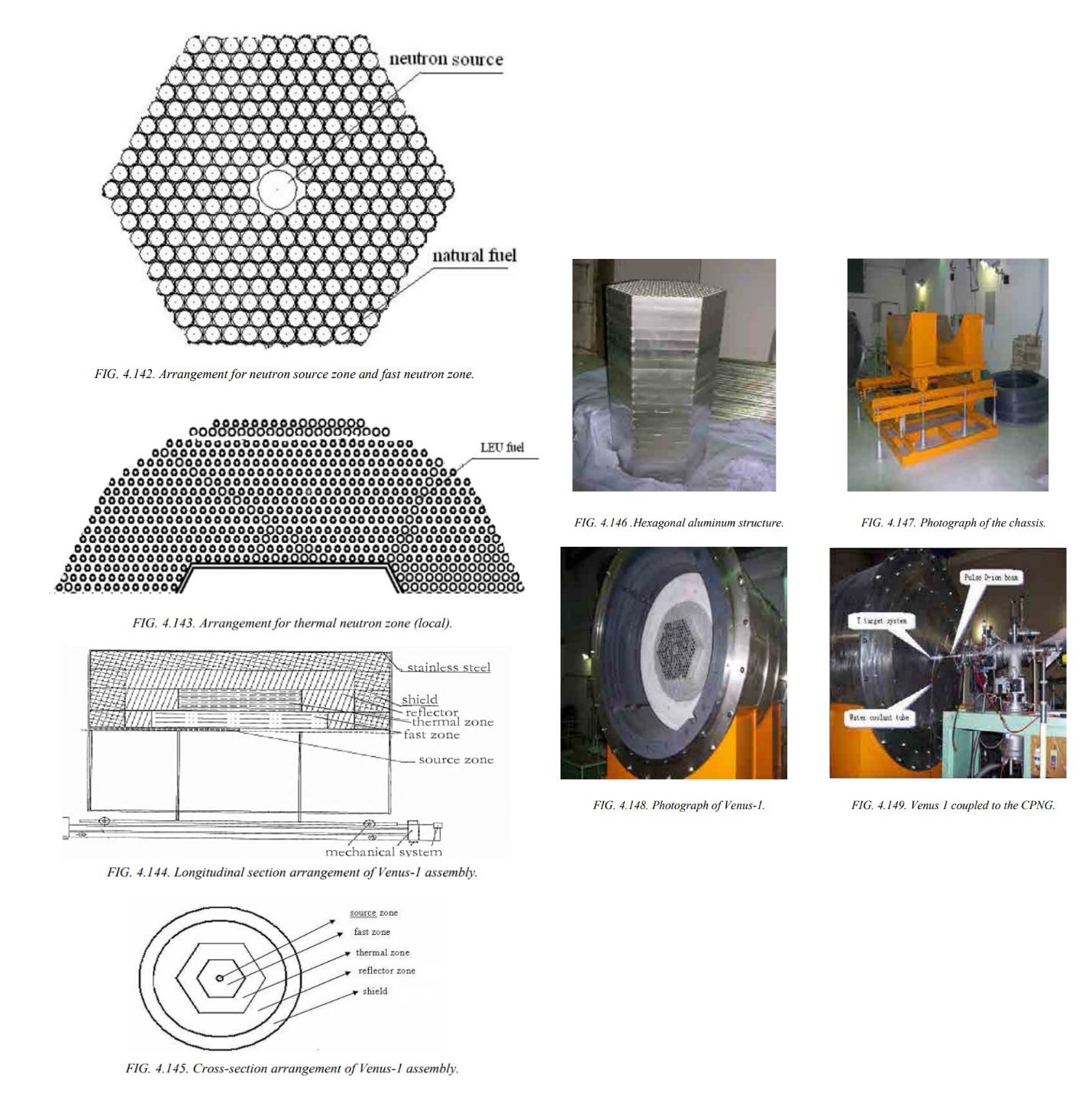

More significantly, CIAE has constructed a series of zero-power devices for reactor physics experiments crucial to the development of ADS and lead-cooled reactor technologies. Venus I, a subcritical reactor with a coupled thermal and fast neutron core, began operating at CIAE in July, 2005 – a milestone of ADS research while supported by the 973 national program in the early 2000s. In December, 2016, Venus II, a fast neutron device allowing reactor-target coupling experiments in critical and subcritical modes, reached criticality at CIAE. The device was developed jointly by CIAE and the Institute of Modern Physics over four years with the support of the ADS special project. As a testing platform, it is flexibly designed with the ability to switch between water- and lead-cooled operation and among various heavy metal targets. Intended to support the engineering phase of the ADS program, it is used to validate ADS design software, calibrate databases, and verify core instrumentation. Subsequently, in October, 2019, Venus III reached criticality at CIAE following two years of development. The device was oriented toward the validation of engineering solutions for both lead-bismuth-cooled fast reactors and accelerator-driven subcritical reactors as their construction draws nearer.

Venus I has a coupled core with a thermal neutron zone outside the fast neutron zone, which in turn surrounds the neutron source | Source: IAEA

The heavy metal targets and assembly of the VENUS II zero-power device | Source: CIAE

ADS technology, if it is commercialized someday, will have significant implications for nuclear nonproliferation and safeguards. Most obviously, ADS systems will allow the breeding of weapons-usable fissile materials such as Pu-239 without the construction of a critical reactor and therefore without the usual technical signatures. Since accelerator-driven reactors can operate without fissile or fertile materials in their core and can switch between subcritical and critical modes of operation, the profile of minor actinides and fission products in the irradiated material could be much more complex, and it is unclear how difficult it would be to detect diversion and misuse. As noted in one of the only studies of ADS safeguards by Sandia National Laboratories, it remains a challenge simply to understand the signatures of ADS-irradiated materials. Moreover, as the power of an ADS reactor can be adjusted simply by regulating the energy of the proton beam and therefore the intensity of spallation reactions producing external neutrons, it will be necessary to monitor the power of the particle accelerator and the spallation target. If a thorium fuel cycle were to be introduced alongside the ADS concept, then safeguards must also adapt to complications arising from the U-232 and Pa-233 streams.

The safeguarding of reprocessing operations will also present challenges. The minor-actinide and fission-product-rich fuel of an ADS reactor will emit such intense heat and radiation as to require on-site reprocessing using novel pyroprocessing, including AIROX, technologies. Tested extensively in the 1950s and 1960s, the AIROX process involves the exposure of spent fuel rods to high temperatures to convert the uranium oxide to powder form and volatilize some of the contained fission products before repalletizing and sintering the oxide into “fresh” fuel elements. Subsequent development enabled the removal of certain rare earths during reprocessing as well. On the one hand, pyroprocessing, insofar as it does not require the fine partitioning of transuranics, does not produce stocks of pure plutonium in ways the current PUREX method does, thus reducing the potential for proliferation. For instance, Chinese proponents of AIROX – entailing the mere separation of volatile fission products and rare earths with large neutron absorption cross-sections – argue that it is a proliferation-resistant feature. On the other hand, in case states with comprehensive safeguards agreements adopt ADS systems with the accompanying reprocessing infrastructure, current PUREX-based safeguards methodologies will have to be thoroughly revised, and existing safeguards technologies will have to be adapted to the much higher heat loads and radiotoxicity of the materials in an ADS fuel cycle.

Having renounced spent fuel reprocessing decades ago and opted for an open fuel cycle, the United States is not in a position to compete in the development and deployment of ADS systems. However, it may wish to participate in associated standard-setting, which may require keeping technical pace. Whether ADS systems do become a feature of countries’ nuclear fuel cycles, their introduction will have significant implications for the sustainability of nuclear power and nonproliferation worldwide.

The CiADS construction site in January, 2020 | Source: Institute of Modern Physics, CAS

The CiADS construction site in October, 2023 | Source: Institute of Modern Physics, CAS

RFQ cavity of the Chinese linear accelerator prototype | Source: Institute of Modern Physics, CAS

Do you know about Chinese projections/plans/studies regarding further reactor construction time reductions? The best current projects such as Zhangzhou already approach 5 years.

What part of the plant is the limiting factor at the moment? The reactor/containment building, I suppose?

Does China also have/allow private nuclear power projects? The US and Europe currently have a very active SMR startup scene with many different designs being developed (if they cross.thebfinish line, we will see).

Thank you very much for the detailed article. Chinese nuclear is bit of a black box for the Western readers, so very useful article. The minor actinide burning progress is potentially very important for the global success of nuclear power, since long lived waste is one of the (if exaggerated) counterarguments.

Fuel reprocessing and waste separation leads to more low and intermediate level waste. To what extent does the AIROX differ from PUREX in this regard?